Explain Briefly the Different Casting Processes

These castings are usually large in size. Create a wax pattern for your investment casting.

Classification Of Casting Processes Download Scientific Diagram

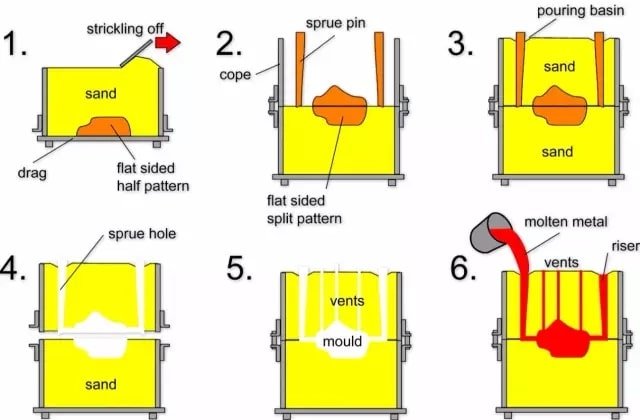

The six basic steps in making sand castings are i Pattern making ii Core making iii Moulding iv Melting and pouring v Cleaning Pattern making - Pattern.

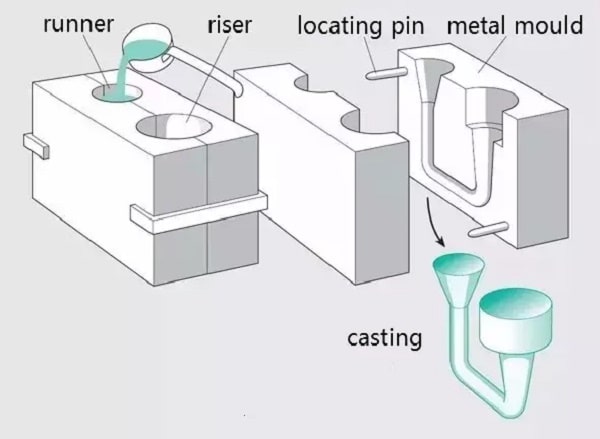

. Die casting is a permanent-mould casting process in which the molten metal is injected into the mould cavity under high pressure. Tooling Making is the first step for investment castingsThat is the basic to achieve precision products. Plaster Casting Process - Sand casting process with use of Plaster to fill gaps Permanent mold casting Metal casting process that employs reusable molds Rapid casting Use of 3-d.

Typical pressures are 7 to 350 MPa. Casting processes can be broken down into two broad categories. So in order to have a good surface finish the final product of the casting is machined with the help of a lathe machine milling machine shaper machine slotting machine.

Investment Casting Process. There are various terminologies associated with the centrifugal casting process out of which these three are important. Hot-Chamber Die Casting It is the most popular type among the.

The defect caused due to misalignment of upper and lower part of the casting and misplacement. In Sand Casting Process the Mould is made up of Sand whereas in this process the mold is. It occurs when loose sand washes into the mold cavity and fuses into the interior of the casting or rapid pouring of the molten metal.

Permanent mould processes. Replica of the part to. Expendable mould processes.

Arrow_forward Q3bExplain in detail different components of a gating system. There are two main types of die casting process. Skeleton pattern is used for castings which have simple size and shape.

The various casting defects that appear in the casting process are. The casting process is the manufacturing process in which molten material such as metal is poured into the casting cavity or mold of the desired shape and allowed to harden or solidify. Ad A superb supplier specializing in invetment casting process and CNC machining production.

Die Casting Process is different from the Sand casting process with respect to the mold only. Years of experience in casting OEM production to meet your various requirements. Let us look into both the types in brief here.

It is the Process in which molten metal flows by gravity or other force into a mold where it solidifies in. The only disadvantages of skeleton types of patterns. Years of experience in casting OEM production to meet your various requirements.

This stage is usually completed using advanced casting wax. 27 What are the casting defects arises due to faulty processes in casting explain each type with neat sketch. Shrinkage Raining and Cast Removal.

With expendable mould processes the moulds are. During cooling of the material in the Casting process in all the three stages the material is getting shrinking reducing its dimensions or volume. Ad A superb supplier specializing in invetment casting process and CNC machining production.

Facts One of the earliest metal shaping methods known to human being. Such tooling or pattern will be precision machined by our CNC. I Loose ramming of the sand.

10 Different Types Of Casting Process Machinemfg

No comments for "Explain Briefly the Different Casting Processes"

Post a Comment